Light comes in three parts – red, blue, and green. It’s a bit more complicated than that, but this will do for now. When something appears white, it is because it is reflecting all three colours, and absorbing none. At the other end of the scale, if something appears black, they are absorbing all of the visible light, and reflecting none of it back. All colours in all things lie somewhere between these extremes, absorbing some light, and reflecting back part of a specific bracket which is what gives us colour.

Plants usually reflect the green part of the light spectrum, hence their green colour. They also have chlorophyll in their leaves, which allows them to convert light into energy for growth. Chlorophyll comes in several different varieties, but the two you will find in green plants everywhere is chlorophyll a, and chlorophyll b. Chlorophyll a is what allows the plant to convert energy from the ultra-violet end of the light scale, and chlorophyll b converts energy from the infra-red end of the light spectrum.

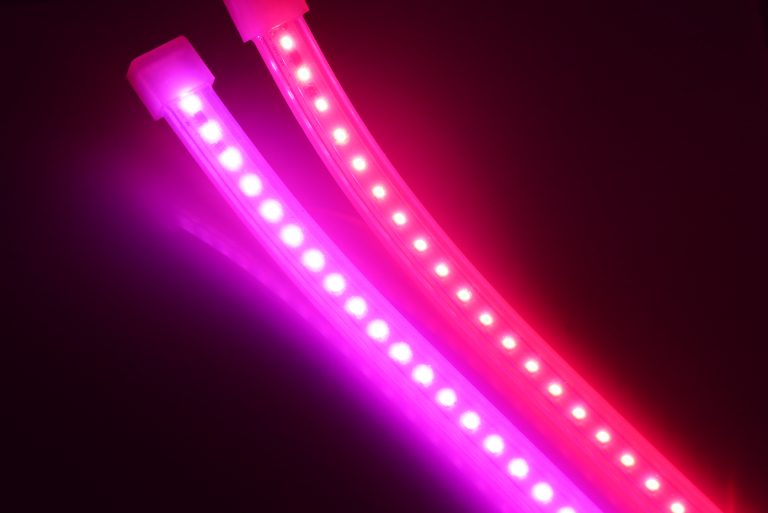

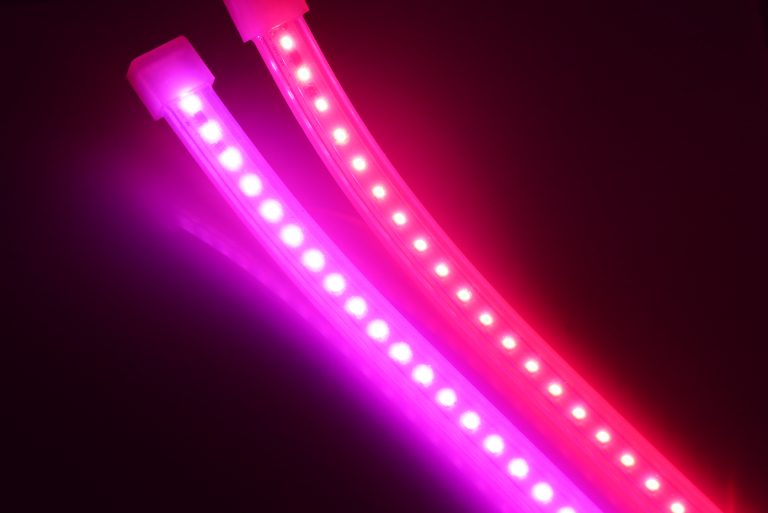

This is why you will often find LED lighting designed for horticulture gives off a purple light. They are providing light in both the blue and red parts of the spectrum that the plant needs for maximum growth potential.

The other thing to consider when looking at horticultural lighting is the amount of light they give off. It won’t make much difference if you’re using the right colour light, if the beam is too weak to matter. This is rated in Lumens (lm). An old 60 watt filament bulb, for example, would give off around 800-850 lumens, or to talk the technical talk, around 13-14 lumens per watt (lm/W). In comparison, an LED light that gives off the same amount of lumens, would only need to be rated at about 11.5 watt, so barely 20% of the power needed.

As well as the obvious power savings, LED lighting technology also means that we can generate the same amount of light as an old bulb, while giving off just a tiny fraction of the heat a filament bulb generates. This is part of how we can generate the same amount of light with a far lower wattage – a far lower energy loss due to heat waste.

American Bright Optoelectronics Company has recently launched a new range of horticultural LED strip lighting, making them the first company to market an efficient and industrial scale IP67 grow light system. It is suitable for use in both vertical and horizontal applications, and is available in both DC and AC format, depending on length and voltage. The maximum length of the lighting strips can be up to 98 feet, or 30m. At this length you are limited to a 240 volt AC power supply. The next length is 65ft, or 20m, which can be lit using a 120v AC power supply, and the final, shortest length available is just 10ft, or around 3m. This is the maximum length you can use if planning on using a DC power supply.

If you’re interested in finding out about any of American Bright’s products, including these horticultural strip lights, please do not hesitate to contact us.