Building computers for use in hazardous environments can be a tricky business. The specifications of a PC needed for use on an oil refinery is very different to the requirements of one being used in a clean room laboratory or a food packaging plant, for example. This is why Daisy Data Displays offers very few off-the-shelf models, and instead give you, the customer, all the options you could want.

Daisy Data computers cover four key industries: the military, oil & gas, food & pharmaceutical processing, and flight simulation. While computers built for each of these industries have their unique differences, all of them are customizable in several key ways.

Military

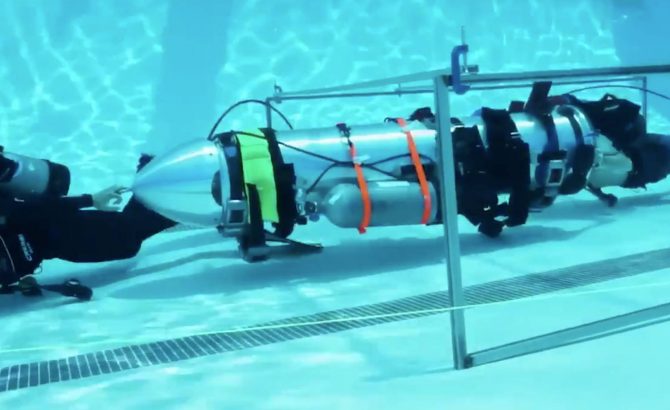

Daisy Data’s military hardware is designed to withstand any environment US troops are sent to, and anything that might be thrown at them. Meeting mil-spec (military specification) targets, Daisy’s ruggedized hardware is well suited to all fields of combat, from high altitude combat fighters, down to high pressure, high humidity submarines, and everywhere in between. Systems are designed to be able to withstand the vibrations of a helicopter, through to the recoil of a tank firing a shell.

In the heat of battle, dependable equipment is essential to the success of the mission, and Daisy Data Displays will help get it done.

Oil & Gas

Oil and gas producers often work in some of the harshest (and dirtiest) conditions on the planet, and their technology needs to be able to reflect that. With that ideal in mind, Daisy Data Displays has created some of the toughest computers the world has ever seen, ranging from ATEX rated, portable rugged computers, through to wall or panel-mountable touchscreens in solid steel cases. They are specifically designed to be shock and vibration resistant, and withstand temperatures of -40 – 65 Celcius. The various systems on offer also comply with a number of third party certifications for safe computing in hazardous environments.

Food & Pharma

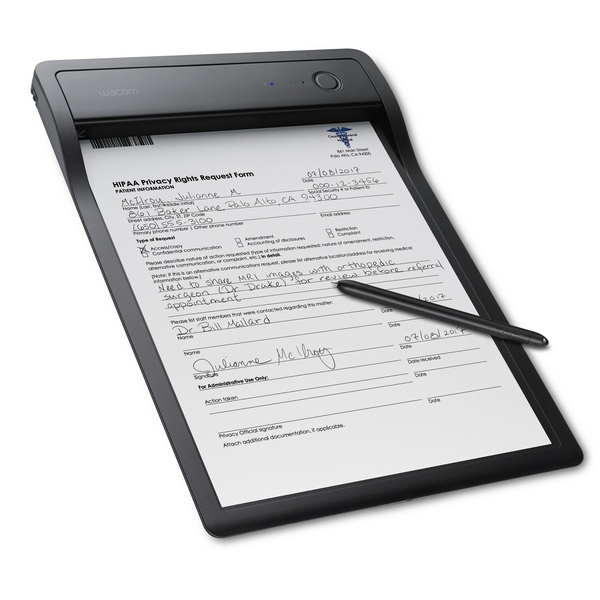

Food and pharmaceutical processing facilities have unique requirements, clean rooms, corrosive environments, frequent wash downs, and so on. All of Daisy Data’s food & pharmaceutical range are designed to be resistant to such rigours, including FDA certification for the US market, or the Food Standards Agency here in the UK. All Daisy Data computers for this industry are constructed out of corrosive resistant materials, and are typically waterproofed.

Flight Simulation

Supporting both military and commercial flight applications, Daisy Data understand the importance of teaching your pilots properly, using the correct technology. This is why Daisy Data’s flight simulation range of products are capable of doing just that, utilizing both capacitive and resistive touchscreens, SAW, night vision goggles filters, and impact-resistant polycarbonate viewing windows. Daisy Data’s flight simulation units maintain form, fit, and functionality, allowing for backwards compatibility.

Make It Daisy, your Way

As has already been mentioned, Daisy Data Displays offer unprecedented customization options for all of their products. This ranges from mounting options, to touchscreens, to keyboards, to pointing devices, and stops at just about every place in between. You can even choose specific components to go into the computer itself – more memory, hard drive space, graphics, and so on, all with the final option of operating systems and software.

What’s Available?

Out of Daisy Data’s products, the only ones we have available ‘as standard’ are Daisy Data’s keyboards. These are listed on our website, here. The reason we only offer the keyboards on our website is because all of their other systems have far too many options open to them.

If you would like to discuss requirements for a hazardous environment computer system, please do not hesitate to contact us. We will happily go through all of the options with you, and once we have a specification sheet, we will provide a competitive quote, bespoke to your needs. Just give us a ring on 01670 361261 and speak to Jimmy, or email him at [email protected].